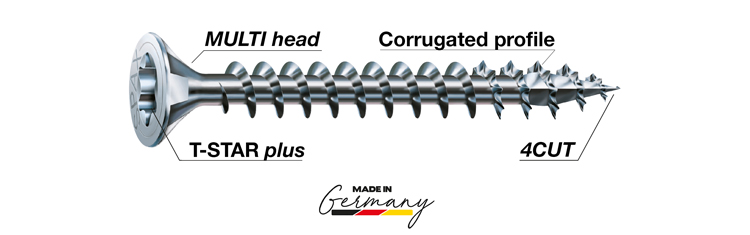

SPAX - The properties

T-STAR plus force application

Guarantees an even firmer (tool) hold and better SPAX guidance. For optimal force transmission, even when working overhead.

The MULTI head

The innovative pocket segments help with every application. On wood, they have a milling effect, and on metal, they function like a brake to prevent over-tightening.

The surface

The SPAX offers high corrosion protection through the WIROX and YELLOW coating. The chromium(VI)-free coating also protects the environment.

The corrugated profile

The unique cut of the thread all the way to the point ensures rapid, safe fastening and effortlessly pulls the screw into the wood.

The 4CUT

The point significantly reduces wood splitting and pre-drilling is made unnecessary for most wood types. The insertion moment is also effectively reduced. The cutter on the thread run-out expands the wood even more and the thinner shank no longer produces friction. This keeps the torque low and saves energy. This means more fastening with a single battery charge.

More than just a screw: the SPAX. With MULTI head, corrugated profile and 4CUT point.

SPAX. Build your dream!

| Screw head | ||

| The countersunk head (or flat countersunk head) is the most frequently used head geometry. It has a conical shape and is designed as a 90° MULTI head at SPAX. It can be countersunk optimally into wood materials and closes flush with the surface. | |

| The pan head is an almost spherical shape of the screw head. This head shape is ideally suited for the visible fastening of metal fittings to wood. | |

| The raised countersunk head screw, the panhead has a flat, lenticular head geometry. Due to the special, ornamental shape, this is often used for visible, ornamental screw fastenings of furniture or skirting boards. | |

| The S point describes the pin-shaped recess that connects to the force application inside the screw head. Due to the hole, special caps for this type of screw hold particularly well and are secured against falling out. | |

| The flange head is a flat-face head that is often used in practice in the furniture industry for fastening hardboard to the back of cabinets and shelves. The flat, plate-like head of the screw saves space and increases the contact area on the fibreboard. The head cannot be easily pulled through the wood panel. The back panel head is available in the SPAX range up to a thread outer diameter of 5 mm. | |

| The washer head of the screw increases the contact surface on the workpiece and thus guarantees considerably higher head pull-through forces compared to a countersunk head screw. In this way, the SPAX washer head enables better tight tightening of the wood. The washer head is available in the SPAX range from a thread outer diameter of 5.0 mm. | |

| The SPAX with cylindrical head can be easily countersunk into the wood and, thanks to the small head diameter, enables an almost invisible screw connection. Due to the low splitting effect when countersinking the head, SPAX with cylindrical head are particularly popular in timber construction or decking applications. | |

| Thread forms | ||

| The partial thread only extends over part of the screw length. Partially threaded screws are particularly suitable for fastening wooden panels to wooden beams. The non-threaded part should always be chosen so that it is at least equal to the thickness of the panel that is to be screwed. In this case, the thread tightens in the lower piece of wood, while the upper piece of wood is pulled tightly to the lower one via the screw head. | |

| The full thread extends partially over the entire length of the screw. Screws with a full thread are particularly suitable for absorbing very large tensile and compressive forces in joints or for reinforcing wooden components. | |

| The fixing thread is a second thread just below the head of the SPAX. The fixing thread guarantees a secure and permanent connection between two pieces of wood. Especially when installing wooden floors indoors with the SPAX installation screw or when building wooden terraces outdoors with SPAX-D in stainless steel, the fixing thread holds the deck board permanently on the substructure. Creaking noises of the floor construction are thus minimised. | |

| Material/Surfaces | ||

| The new, exclusive WIROX coating from SPAX offers a higher level of corrosion protection in the neutral salt spray test than the conventional bare zinc coating in accordance with the standard and has a significantly higher surface hardness. This makes it ideal for outdoor use in structures such as carports or pergolas where they are not exposed to direct weathering. WIROX also has a significantly higher surface hardness than, for example, the conventional yellow zinc coating or zinc flake coatings and is therefore more resistant to mechanical stress. | |

| YELLOX is chrome(VI)-free and therefore more environmentally friendly than the usual yellow zinc coating. And this is true both in production and in use. Nevertheless, it is at the same time more resistant to corrosion than the conventional bright or yellow galvanised screws. YELLOX is an innovation that benefits the environment and the user. | |

| Burnished screws are made of steel whose surface has been refined by a chemical process. This surface has a lower corrosion resistance compared to a galvanised screw and should only be used indoors. Burnished screws have a brownish appearance, making them ideal for furniture restoration applications with dark or antique woods. | |

| Nickel-plated - The application of a nickel alloy protects the material of the screw from corrosion and at the same time gives it a chrome-coloured, slightly yellowish appearance. We recommend using it indoors only. | |

| SPAX stainless steel screws are particularly suitable for use outdoors and in damp rooms. They are available in the stainless steel A2 version for outdoor applications where they are exposed to direct weathering, as well as for use in damp rooms (for example, kitchen and bathroom). For coastal applications, we recommend the stainless steel A4 version. Stainless steel is characterised by a high chrome content. This forms a protective layer on the surface of the material. Other alloying components such as nickel, molybdenum, manganese and niobium lead to even better corrosion resistance. | |